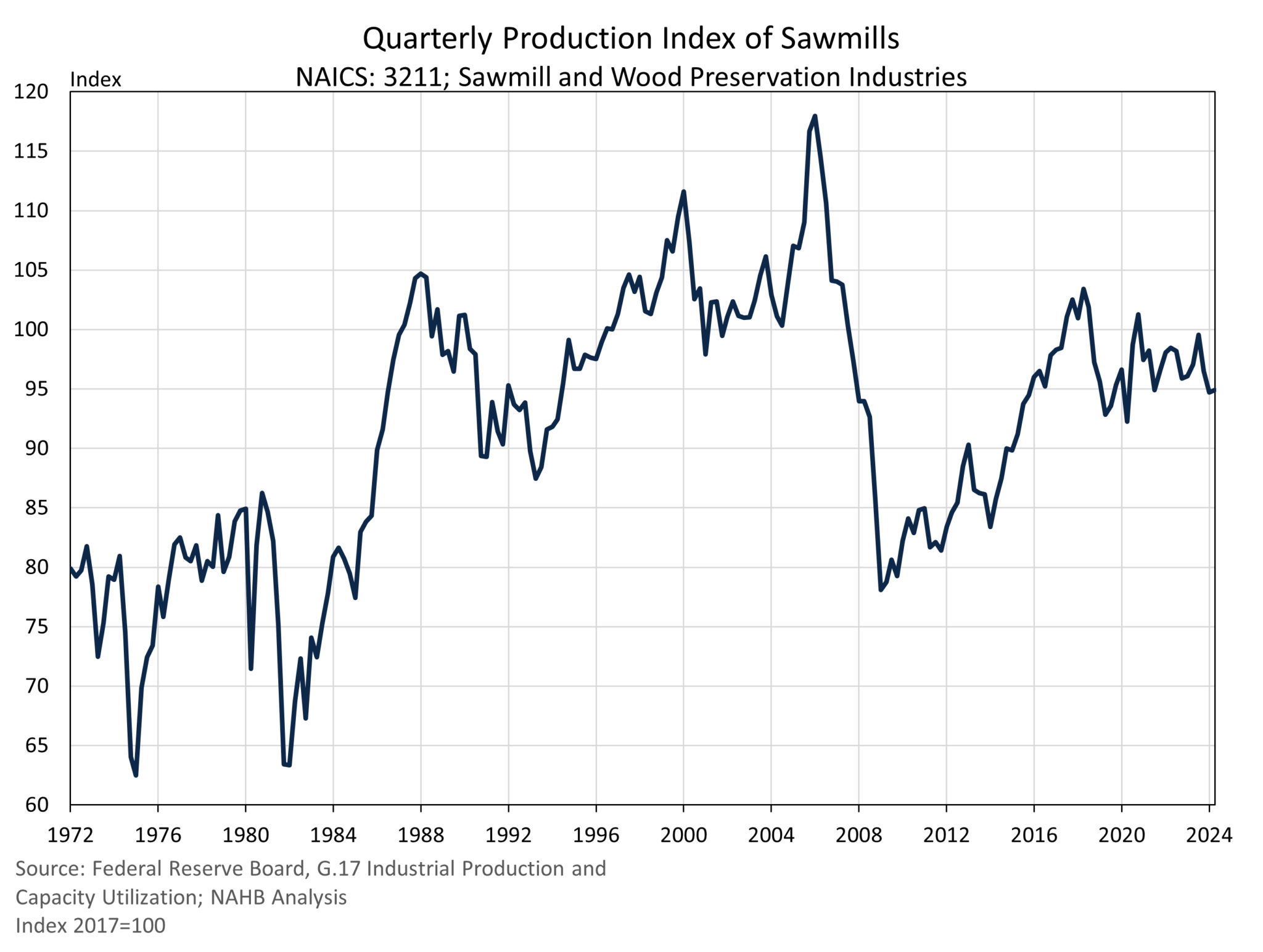

Second-Quarter Sawmill Production Rises

The production index for sawmills and wood preservation businesses increased by 0.2% in the second quarter of 2024.

According to G.17 data, this was the first increase in real output since the third quarter of 2023, following two consecutive declines.

The index was 2.2% lower than a year ago, the greatest year-over-year reduction since a 4.7% drop in the fourth quarter of 2021.

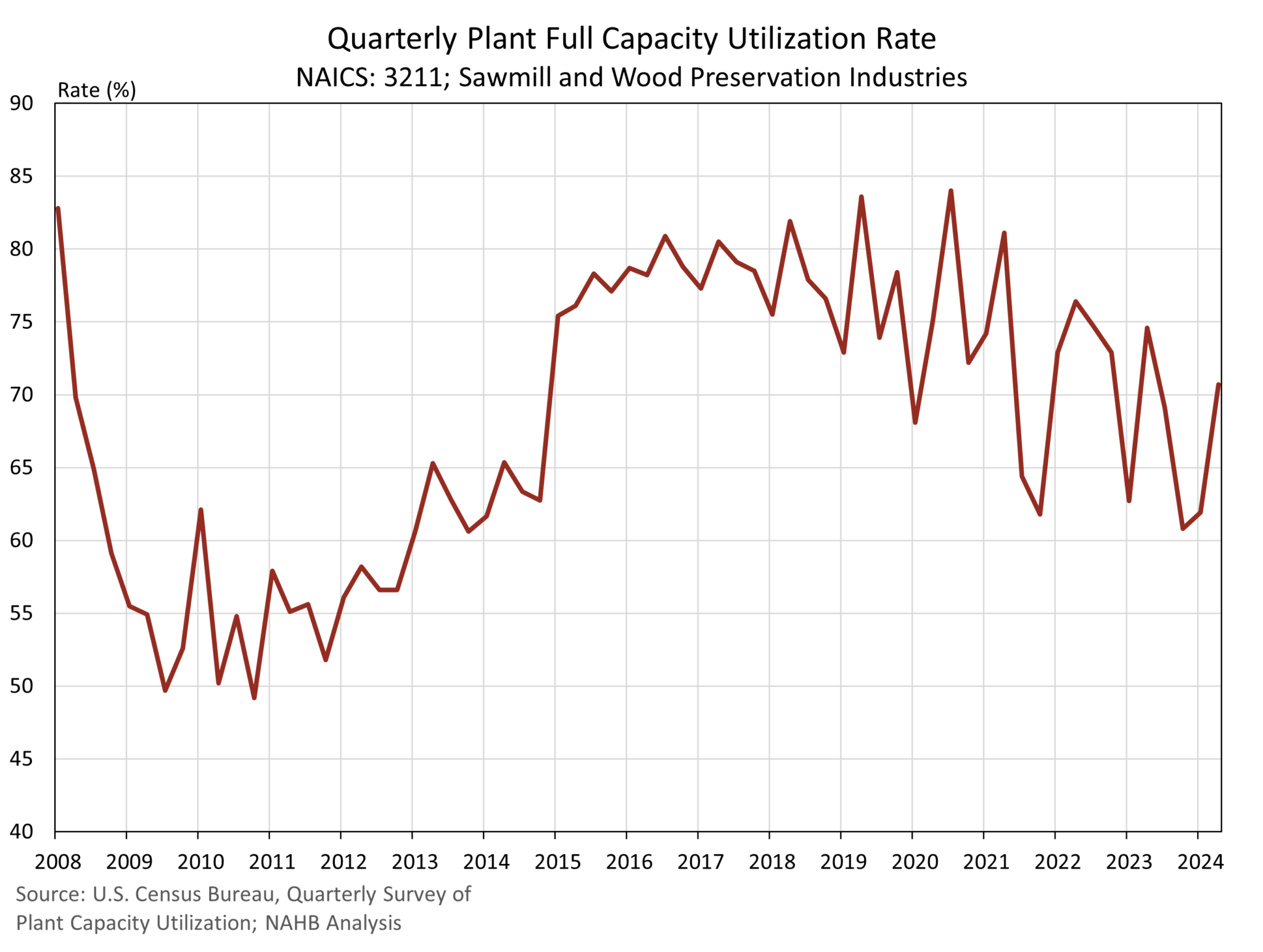

Quarterly Survey on Sawmill Capacity Utilization

The Census Bureau’s Quarterly Survey of Plant Capacity Utilization is another useful resource for learning more about the sawmill and wood preservation businesses. This data is based on quarterly surveys of domestic manufacturing plants in the United States, and it includes a subindustry grouping of sawmills and wood preservation enterprises.

The study estimates utilization rates based on full production capability, which means that utilization rates are calculated by taking the market value of actual production during the quarter and dividing it by the estimated market value of what the firm could have produced at full capacity.

In other words, the rate represents how much production capacity is needed to generate current output.

The sawmill and wood preservation industry’s full utilization rates increased dramatically during the quarter, rising from 61.9% to 70.7%. Given this increase, it’s surprising that production hasn’t increased significantly.

These enterprises’ average plant hours per week increased from 47.9 in the first quarter to 57.7 in the second quarter.

Employment

Employment in sawmill and wood preservation firms increased for the first time in six quarters, reaching around 89,400 in the second quarter.

The Great Recession had a significant impact on this industry, with employment dropping from 105,630 in the first quarter of 2008 to a series low of 80,470 in the fourth quarter of 2009.

Employment increased from this low to 91,000 in 2014, and it has remained around this level for the past decade.

Capacity Index Estimate

By combining the production index with the utilization rate, we can create a rough index estimate of the current output capacity of US sawmills and wood preservation enterprises.

The production capacity index is estimated quarterly, as shown below. This capacity index represents the real production if all enterprises were operating at full capacity.

Due to the data’s volatility, we compute a moving average of the utilization rate, production index, and capacity index.

These are four-quarter moving averages, which are displayed below to give a more complete perspective of the industry.

Based on the data presented above, sawmill output capacity has increased since 2015, yet it remains lower than peak levels in 2011. Sawmill production continues to rise, owing to stronger utilization levels than in the past, as illustrated in red above.

Much of the capacity expansion has occurred recently, as utilization rates have declined while production has remained strong.

Despite the fact that the United States is the leading producer of softwood lumber in North America, present capacity and output levels do not match demand from American customers.

According to Census foreign trade data, imports continue to be crucial in supplying U.S. demand for softwood lumber. In September alone, imports of softwood lumber totaled 1.1 billion board feet.

In September, Canada was the primary nation of origin, exporting 987 million board feet to the United States.

The current average antidumping/countervailing duty rate on these Canadian imports is 14.5%. U.S. producers say that Canadian provincial governments subsidize softwood lumber production, allowing Canadian companies to sell lumber at lower-than-market costs.

The data show that after the softwood lumber accord expired in 2015, tariffs on Canadian softwood lumber have significantly benefited the U.S. lumber industry, allowing for increased production capacity.

[Read more about this topic on Eyeonhousing.org]